How Golf Balls Are Made: Inside a Professional Manufacturing Factory

In golf, the golf balls often one of the most overlooked, yet crucial, pieces of equipment. A seemingly simple little white ball actually embodies the results of materials science, precision manufacturing, and rigorous testing.

This article will take a professional perspective on golf ball manufacturing, systematically analyzing how golf balls are made, and taking you inside a professional golf ball factory to understand the complete process of high-quality golf ball production, from raw materials to finished product.

The Core Logic of Golf Ball Manufacturing: Performance Determines Structure

In a professional manufacturing system, golf balls are not simply “the harder the better” or “the softer the farther,” but are designed around three core performance objectives:

- Initial velocity and distance: Energy conversion efficiency at the moment of impact

- Spin control: Short game stopping power and stability

- Durability and consistency: Long-term use and batch consistency

Therefore, modern golf ball manufacturing usually starts with structural design, rather a than directly entering production.

Basic Golf Ball Structure Types

In a professional golf ball factory, golf balls are typically categorized into the following structures:

1. Two-piece balls

- Large rubber core

- Outer layer of Surlyn or similar material

- Features: Long distance, durable, suitable for beginners

2. Three-piece balls

- Rubber core + intermediate energy layer + soft outer shell

- Balances distance and spin

- Suitable for intermediate players

3. Multi-layer balls (4–5 layers)

- Multi-material composite structure

- Precise spin zone control

- Often used by professional or low-handicap players

Lanifun customizes structural proportions and material formulations in product development based on the needs of different players.

Core Manufacturing Process Analysis: How Golf Balls Are Made

1. Rubber Core Manufacturing

The “heart” of a golf ball is the rubber core.

- Main material: Synthetic rubber (Polybutadiene)

- Additives such as zinc acrylate and peroxide are added

- Molded under high temperature and high pressure

The core density and elasticity directly affect the initial ball speed, making it the most critical first step in golf ball manufacturing.

2. Mid-Layer and Energy Layer Formation

For three-layer and above structured balls:

- Using injection molding or coating processes

- Different materials control the energy release rhythm

- Improving feel and directional stability during impact

Professional golf ball factories continuously adjust the layer thickness tolerance through laboratory testing, usually controlling it within ±0.05mm.

3. Cover Manufacturing

The cover determines the “feel” and spin performance of the golf ball.

Common materials include:

- Surlyn: Durable, low spin

- Urethane (polyurethane): Soft feel, high spin

Lanifun’s high-end series uses a multi-layer polyurethane composite cover, enhancing short game control while maintaining durability.

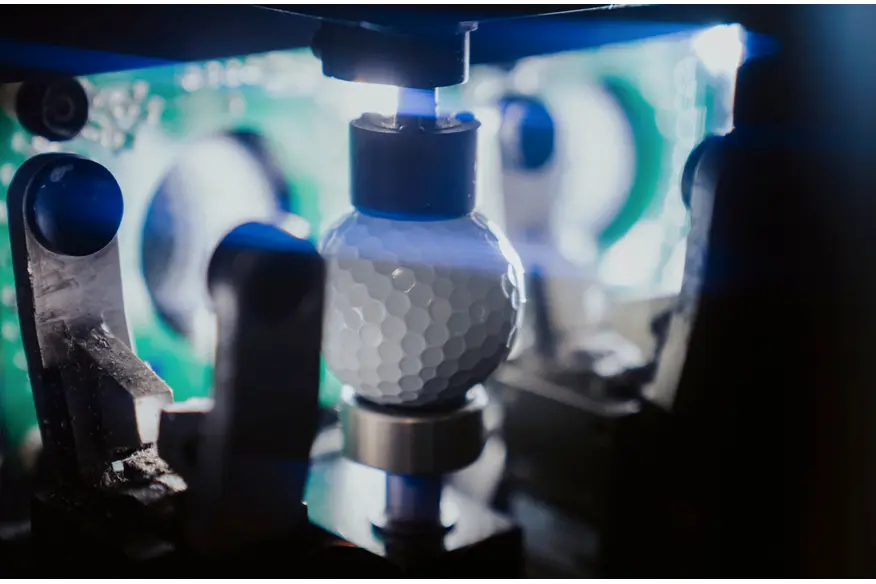

4. Dimple Design and Formation

Dimples are not just decorative, but are the core of aerodynamics.

- Common number: 300–400

- Depth and angle affect lift and stability

- Formed in one go using precision molds

In the process of how golf balls are made, dimple design often requires extensive wind tunnel data and real-world testing.

5. Painting, Printing, and Surface Treatment

After structural formation is complete, the golf ball enters the appearance process:

- Multi-layer painting to ensure brightness and wear resistance

- UV curing treatment

- Logo and alignment line printing

Professional factories ensure:

- Uniform paint layer thickness

- Does not affect the dimple structure

- Does not peel off easily after prolonged use

6. Quality Inspection: A Key Link in Professional Golf Ball Factories

Truly professional golf ball factories do not ship directly after production is complete.

Routine inspections include:

- Weight consistency testing

- Diameter and roundness testing

- Compression testing

- Initial velocity and spin testing

- Durability impact testing

Lanifun conducts multiple rounds of random inspections before shipment to ensure that each batch of products meets international golf ball standards.

7. Why Factory Strength Determines Golf Ball Quality?

In the global market, golf balls may look similar, but the manufacturing differences behind them are significant. A factory with complete golf ball manufacturing capabilities typically possesses:

- Independent formula and mold development capabilities

- A stable material supply chain

- Precision injection molding and compression molding equipment

- A complete testing laboratory

Lanifun operates based on this manufacturing system, providing stable, highly consistent golf ball products to the international market.

From Factory to Fairway: The True Value of Golf Ball Manufacturing

Understanding how golf balls are made isn’t about creating complexity, but about achieving more controllable performance on the course.

- Consistent hitting distance

- Predictable spin feedback

- Long-term reliability

These all stem from the manufacturing details behind a professional golf ball factory.

Conclusion: Professional Manufacturing Determines the Limits of Golf Balls

Golf ball manufacturing is a highly systematic engineering process. From the rubber core to the dimple design, from material formulation to quality testing, every link affects the final performance.

For international customers who value product quality and long-term partnerships, choosing a manufacturer with complete golf ball manufacturing capabilities is crucial to ensuring product competitiveness.

Lanifun will continue to deeply cultivate the field of golf product manufacturing, providing reliable, high-performance golf ball solutions to the global market with professional factory standards.