How Golf Balls Are Made: Inside a Professional Manufacturing Factory

In golf, the quality of the golf ball directly affects driving distance, spin control, and overall feel. However, many people don’t understand how golf balls are made, nor do they understand the truly professional golf ball manufacturing process. This article will take you inside a professional golf ball factory to comprehensively analyze the manufacturing process of golf balls.

What is Golf Ball Manufacturing?

Golf ball manufacturing refers to the complete industrialized production process, from raw material preparation and mold forming to finished product testing. Modern golf balls typically use a multi-layer structure design, rather than a simple rubber sphere.

A standard golf ball usually consists of the following structures:

- High-elasticity rubber core

- Energy-transferring mantle layer

- High-wear-resistant outer cover layer

- Precision aerodynamic dimples

In a professional golf ball factory, every ball undergoes double control through automated equipment and manual inspection.

How Golf Balls Are Made: Complete Manufacturing Process Analysis

1. Rubber Core Molding

In the golf ball manufacturing process, the first step is the manufacturing of the rubber core. Lanifun uses high-elastic synthetic rubber, molded under high pressure in a precisely temperature-controlled environment, ensuring the core has:

- High rebound rate

- Stable compression ratio

- Precise weight control

This process determines the initial velocity and energy transfer efficiency of the golf ball.

2. Intermediate Layer Coating Process

Adding one or more layers of elastic material to the outside of the core is one of the most crucial steps in how golf balls are made.

Lanifun uses multi-layer composite coating technology, allowing the ball to achieve:

- Stronger energy transfer

- More stable spin control

- Softer impact feedback

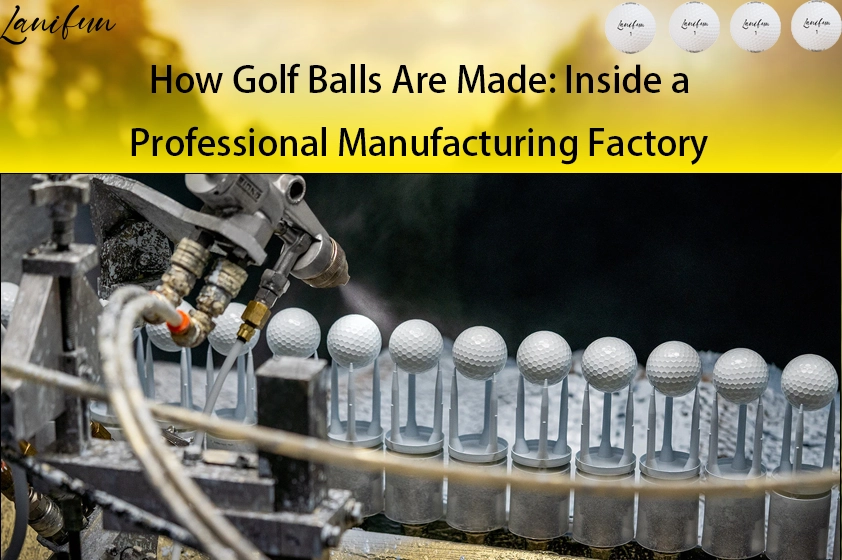

3. Outer Shell Injection Molding

The outer shell directly determines the durability and feel of the golf ball.

In Lanifun’s golf ball factory, the outer shell typically uses:

- High-grade TPU polyurethane material

- High-performance ionomer material

Formed through a precise injection molding process, the surface finish meets competition-level standards.

4. Dimple Design and Aerodynamic Optimization

Many people are most interested in the dimple design on the surface when considering how golf balls are made. Lanifun achieves this through:

- Wind tunnel experiments

- Fluid dynamics simulations

- Actual ball striking tests

Continuously optimizing the dimple structure to give the ball stronger wind resistance and flight stability.

Professional Golf Ball Factory: Lanifun's Manufacturing Advantages

As a professional golf brand for the international market, Lanifun owns a modern, intelligent golf ball factory with the following advantages:

- Fully automated production lines

- High-precision testing laboratory

- Strict quality traceability system

- Supports OEM/ODM customization services

Throughout the golf ball manufacturing process, Lanifun implements strict process standards to ensure high consistency in every batch of products.

Differences in Manufacturing Methods for Different Golf Ball Structures

In professional golf ball manufacturing, different types of balls use different processes:

Double-layer structure

Focuses on durability and long distance, with a relatively simplified manufacturing process.

Three-layer structure

Balances distance and spin, requiring a more complex coating process.

Multi-layer structure

Designed for professional players, requiring extremely high demands on material selection and production precision.

Lanifun can complete customized production of different structures in its golf ball factory according to customer needs.

Quality Testing: The Final Critical Step in How Golf Balls Are Made

In the final stage of how golf balls are made, every golf ball undergoes a rigorous testing process:

- Weight consistency testing

- Diameter size calibration

- Compression coefficient testing

- Flight trajectory simulation testing

Ensuring that every ball meets professional competition standards.

Why Choose Lanifun?

As a professional brand, Lanifun has significant advantages in the field of golf ball manufacturing:

- Experience in golf product manufacturing

- Owned standardized golf ball factory

- Stable large-scale production capacity

- Supports global markets and brand customization

Lanifun always adheres to craftsmanship and quality as its core, providing high-performance golf ball solutions to global customers.

Future Trends in Golf Ball Manufacturing

With technological advancements, how golf balls are made is constantly being upgraded, and future trends include:

- Application of environmentally friendly new materials

- More intelligent structural design

- Refined aerodynamic optimization

- Data-driven ball performance research

Lanifun also continues to increase R&D investment and upgrade its next-generation golf ball manufacturing technology.

Summary

By understanding how golf balls are made, we can see that behind a small golf ball is a highly professional golf ball manufacturing system. From core design to aerodynamic research, from automated production to rigorous testing, every detail determines performance on the golf course.

As a professional brand, Lanifun, relying on its own modern golf ball factory, continuously provides the global market with stable, high-performance golf ball products, delivering a more precise experience with every swing.